Health food-tablet OEM

• Flat lozenges

• Sugar-coated lozenges

• Hexagonal lozenges

Tablet OEM

Complete and diverse lozenge OEM services to ensure customer product quality

Our company provides a variety of tablet OEM services, with professional manufacturing equipment and strictly controlled processes. Ensure customer product safety and peace of mind. Looking for health food OEM? Are you worried about tablet OEM production? Leave it to Huoyi International, you are most assured to choose a professional tablet OEM manufacturer and health food OEM service, please call to inquire.

What is Tablet Foundry?

Tablet OEM refers to a company (principal party) handing over its pharmaceutical technology and formula to another health food foundry (OEM) for production in order to obtain tablet products. The health food OEM is responsible for the health food OEM process from raw materials to final product packaging, and ensures that it meets the requirements and quality standards of the entrusting party.

In tablet OEM, the entrusting party is usually responsible for designing product specifications, providing formula and technical information, while the OEM party is responsible for the production process and equipment, purchasing raw materials, conducting production, testing and packaging.

The benefits of health food OEM include lower production costs, saving R&D and equipment funds, improving production efficiency and speeding up market launch. However, it should be noted that the entrusting party needs to ensure that the health food OEM has sufficient production capacity, quality control system and production license in compliance with laws and regulations. In addition, communication and coordination between the entrusting party and the health food OEM are also very important to ensure that the final product meets the entrusting party's requirements and standards.

The benefits of health food OEM

Health food OEM is a production method that transforms raw materials and technology into marketable products.

Health food OEM has the following advantages:

-

Professional production technology:

Foundry companies usually have advanced production technology, production equipment and rich production experience, and can provide professional production technology and consulting services.

-

Cost reduction:

Foundry companies usually have the advantage of large-scale production, which can reduce costs, improve efficiency, and have the advantage of economies of scale.

-

Mitigating Risk:

Foundry companies can provide customers with a full range of services such as product development, design, production and packaging, thereby reducing customers' risks and ensuring product quality and safety.

-

Improve Market Response:

Foundry companies can quickly produce products according to customer needs and improve market response speed.

-

Enhance brand competitiveness:

Foundry companies usually have advanced design capabilities and production technologies, and can provide customers with innovative product designs and high-quality production services, thereby enhancing the brand competitiveness of customers.

To sum up, health food OEM can help customers reduce costs, reduce risks, improve market response speed and enhance brand competitiveness, so as to achieve a win-win situation. Therefore, more and more companies choose to produce health food through OEM.

The lozenge manufacturing process usually includes the following steps:

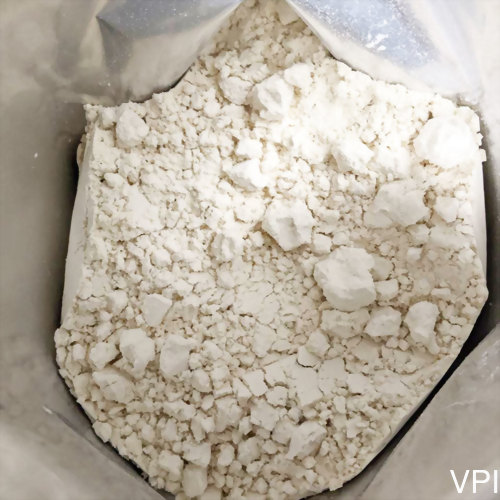

- Raw material procurement: The health food OEM will purchase qualified food OEM raw materials according to the formula and requirements provided by customers.

- Raw material inspection: inspect raw materials to ensure that they meet relevant standards, and check whether raw materials meet customer requirements.

- Mixing of ingredients: According to the customer's formula and requirements, the health food raw materials are mixed.

- Sugar coating or coating: If customers require sugar coating or coating, the health food OEM will provide sugar coating or coating to make the lozenge more beautiful and easier to take.

- Tabletting: After the ingredients are mixed, use a tablet machine to press the mixture into a tablet shape.

- Drying: Dry the compressed tablets to remove moisture from the tablets and ensure stable quality of the tablets.

- Inspection: inspect the dried tablets to ensure that the tablets meet relevant standards and customer requirements.

- Packing: The tablets that pass the test will be packed, including bottled, bagged, boxed, etc., and can also be personalized according to customer requirements.

- Inventory: Warehouse management of packaged lozenges and safekeeping of products.

To sum up, the tablet OEM process in health food OEM includes the steps of raw material procurement, raw material testing, ingredient mixing, sugar coating or coating, tablet pressing, drying, testing, packaging and inventory. Each step is interlocking, and each step needs to be strictly controlled to ensure the quality and safety of the final product.

What is a spinning machine?

Tablet making machine is a machine that compresses powdery or granular raw materials into solid tablets. The pasting machine is usually composed of a series of rollers, moulds, pressure system and feeding system, etc. Its working principle is to make the raw materials tightly compressed into pastilles in the mold through pressure.

Generally speaking, the working process of the ingot machine is as follows:

- Raw material preparation: Prepare the required raw materials according to the formula and mix them.

- Finely crushed: If the raw material is not finely crushed, it needs to be finely crushed.

- Feeding: Put the mixed raw materials into the feeder, and send the raw materials to the mold through the feeding system.

- Compression: In the mold, the raw material is compressed into tablets through a pressure system.

- Tablet unwinding: After the pressing is completed, the tablet is discharged through the ingot unloading system, and the final product is formed.

According to different working methods and product requirements, ingot machines can be divided into single-pressure ingot machines, multi-station rotary table ingot machines, continuous tablet presses and other types. The use of pasting machines can greatly improve production efficiency and ensure product quality and consistency.

-

Arc Lozenge

Arc lozenge refers to a drug form in which the edge of the lozenge is designed in an arc shape. Compared with traditional square or round lozenges, rounded lozenges have softer edges and are easier to swallow, reducing possible injury or discomfort.

-

Flat lozenges

A flat lozenge is a lozenge form whose surface is flat. Compared with other shapes of lozenges, such as round lozenges, square lozenges, etc., flat lozenges have a neater appearance and are convenient for storage and packaging.

-

Sugar-coated lozenges

A dragee is a lozenge form covered with a coating of sugar. It is an oral pharmaceutical preparation, and its sugar coating can form a thin film on the surface of the lozenge to protect the drug from moisture, light, oxygen and other external factors, thereby improving the stability and shelf life of the drug.

-

Hexagonal lozenge

Hexagonal lozenges are a lozenge form that is hexagonal in shape and are also known as hexagonal lozenges. If OEM of hexagonal tablets is required, pharmaceutical manufacturers can seek cooperation with manufacturers specialized in OEM of tablets.

- Other lozenge OEM